Cuddon Freeze Dry provides clients with a commercial advantage. Our freeze dryers can freeze dry anything with a moisture content without damaging its physical structure. Engineered for resilience, our freeze dryers deliver high-quality, efficient and replicable results.

The Benefits of Freeze Drying Cannabis

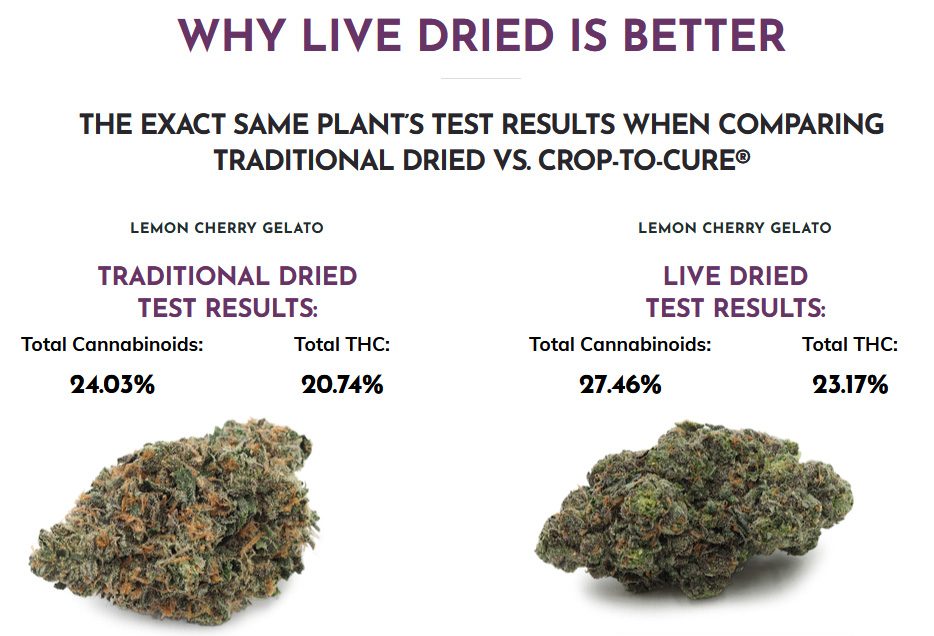

This white paper examines the significance of employing proper lyophilization techniques for drying cannabis and hemp, which is commonly known as “live dried”. By utilizing advanced freeze drying and curing methods, licensed operators can consistently enhance the quality, potency, and shelf life of their dried inhalable flower while bringing it to dispensary shelves in a fraction of the time traditional drying and curing methods typically require (one to two days instead of weeks or months).

Why Freeze Dry?

Freeze drying removes moisture content without heating or damaging a product, unlike other drying processes: during spray drying products are exposed to higher temperatures which could degrade a products bioactivity, while dehydrators shrink products (and can make them rock hard), and baking or grilling products changes their chemical composition.

Just add water! - Or another fluid or flavour. Freeze drying creates a honeycomb texture and retains a product’s size and shape. Due to holes left by ice crystals during the freeze dry process, rehydration is quick and easy.

Cuddon freeze dryers can freeze dry anything with a moisture content. Using fresh, frozen, fermented or cooked products as a starter, clients use our machines for multiple products which can be freeze dried whole, sliced, minced, slurried or in liquid form.

A product without moisture content can be preserved for longer. With quality packaging to block light/UV, heat and oxidization, the ability of a product to downgrade is significantly reduced, increasing shelf life.

Crop-to-Cure® techniques enable cultivators to take their crop from the garden to testing and package ready in a day or two, instead of multiple weeks or over a month. This also allows growers to trim and freeze their crop for future processing on demand, so that they can always offer a fresher, live dried flower instead of being forced to dry their entire harvest all at once.

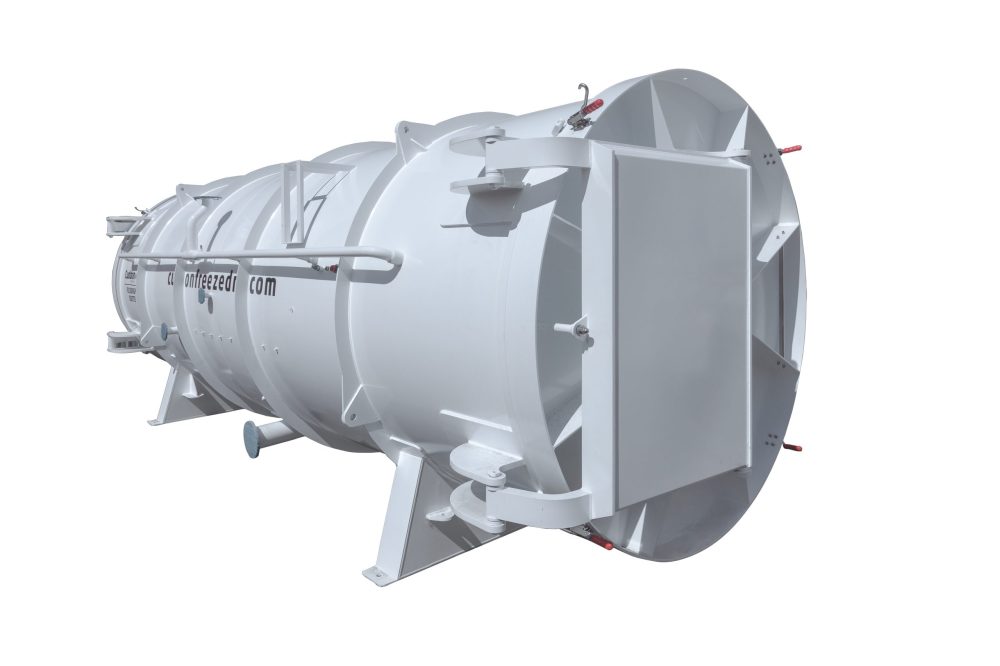

Even some of the largest Cuddon HiLyph edition freeze dryers used in the Crop-to-Cure® process only take up a small portion of the space typically required for standard drying and curing techniques.

When plants are exposed to open environments during the drying and curing process, if humidity controls aren’t perfect, the chance for microbial growth or pest infestation becomes much higher. Lyophilized drying sharply reduces that possibility.

Our Cuddon Freeze Dry machines – The HL range

HL50 Freeze Dryer

The smallest of our custom designed cannabis freeze dryers, the HL50 is based on our FD100GPC model while boasting a few key design changes to optimise it to dry Cannabis. Design features include a very small footprint with a large shelf capacity, plug & play installation, wider shelf spacing as standard and pre-programmed recipes developed specifically for this product.

HL600 Freeze Dryer

The HL600 is based on our FD600GPC model while boasting a few key design changes to optimise it to dry Cannabis. Design features include wider shelf spacing as standard and pre-programmed recipes developed specifically for this product. With over 5 times the shelf capacity of the HL50, this is a true commercial machine capable of high yields of cannabis.

HL1200 Freeze Dryer

Twice the capacity of the HL600, the HL1200 model is based on the FD1200GPC model while boasting a few key design changes to optimise it to dry Cannabis. Design features include wider shelf spacing as standard and pre-programmed recipes developed specifically for this product.

HL1800 Freeze Dryer

The largest of our range, the HL1800 model is based on the hugely successful FD1800GPC model while boasting a few key design changes to optimise it to dry Cannabis. Design features include wider shelf spacing as standard and pre-programmed recipes developed specifically for this product.

Talk to the Team

Terry Duff

Chief Executive Officer

Blair Kibblewhite

Freeze Dry Sales Executive

Region: Oceania & Global

Linc Burgess

Freeze Dry Sales Executive

Lloyd Parks

Freeze Dry Sales Executive

Region: USA, Canada

& South America