Commercial Freeze Dryer Systems

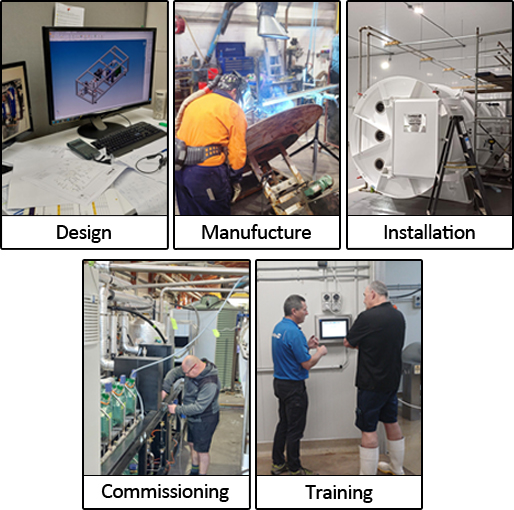

At Cuddon Freeze Dry, we manufacture high-quality industrial freeze dryers and premium freeze-drying equipment for a wide range of commercial applications. As a family-owned and operated business, we were established in 1963 and have made a name for ourselves as leaders in innovation, technology and skill. With a trusted team of designers, steel workers, engineers, fitters and more, we optimise the performance of each freeze dryer to ensure unrivalled customer satisfaction and reliability for years to come.

Our four product ranges are expertly designed for performance and scalability. Our collaborative design and build service combines our decades of expertise with your product requirements, helping us to design and build the ideal commercial freeze dryer to give your business a competitive edge - no matter what industry you’re in. Manufactured in New Zealand, we employ an experienced local workforce who guarantee quality throughout the design and build process to create products you can count on.